The energy storage system is mainly composed of energy storage battery Pack, energy storage inverter (PCS), energy management system (EMS), battery management system (BMS), etc., of which the energy storage battery Pack is the most important part, accounting for 60% of the cost of the entire energy storage system.

The energy storage battery Pack is composed of a battery cell, which is the key device of the electrochemical energy storage system, and largely determines the safety, efficiency and cost of the energy storage system.

With the maturity of the market, the application of the energy storage system in various scenarios such as the user side, the power grid side, and the power supply side continues to deepen, and the energy storage battery is also increasingly moving to the specialized deep water area – that is, around the lower electricity cost, longer cycle life, and higher safety performance, the design and development, process selection and manufacturing path of the battery are more exclusive, and the difference with the power battery is becoming more obvious.

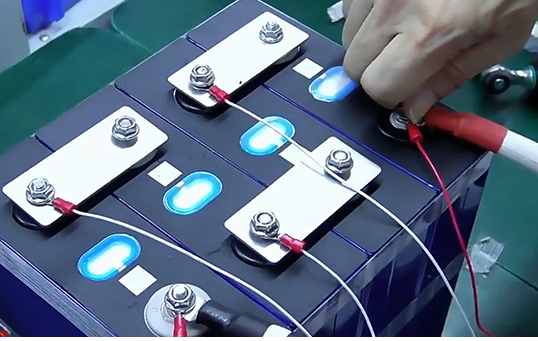

At present, energy storage batteries are mainly lithium iron phosphate batteries. According to the shape classification, the energy storage cell is mainly divided into square, cylindrical and soft pack battery three categories; Divided by capacity, there are mainly 50Ah, 100Ah, 150Ah, 200Ah, 280Ah and other models.

Among them, 50Ah and 100Ah are mainly used for household energy storage, communication energy storage, and small industrial and commercial energy storage. At the capacity level of the cell, the square is mainly 50Ah-100Ah, the soft bag is 30Ah-80Ah, and the large cylinder is 10Ah-50Ah. The smaller cell capacity can improve the battery adaptation, enrich the module form, and bring more diversified power.

150Ah, 200Ah, 280Ah, 280Ah and above models are mainly large-capacity square cells, which are used for large-scale energy storage, including large-scale industrial and commercial energy storage, new energy power stations, power grids and other scenarios.

Household storage cell trend: cylinder becomes an important direction

At present, in the field of household energy storage, the battery cell is still dominated by 50Ah and 100Ah square aluminum shell batteries. However, large cylindrical batteries have become an important direction for household energy storage cells.

First of all, the production efficiency of large cylindrical batteries is high, which can significantly reduce production costs. Cylindrical batteries are the earliest commercial lithium batteries, the production process is mature, and the assembly efficiency is higher than that of square and soft pack batteries.

Second, cylinders reduce the risk of thermal runaway and improve safety. The curved surface of the large cylindrical cell restricts the heat transfer between the batteries to a certain extent, and there is still a large gap even in the case of full contact, which solves the side heat transfer problem of the square and soft pack cell.

Third, the smaller capacity of the single cell improves the battery adaptation, the module form and the amount of electricity are more diverse, and can match different household storage and portable energy storage systems with electricity.

Fourth, the smaller cell capacity is suitable for household high-voltage storage systems. At present, the household energy storage market is still mainly overseas. The European household storage market, especially in the Nordic + German-speaking region, is experiencing product iterations of low-voltage to high-voltage systems, raising the voltage platform to reduce the current, ultimately reducing the system heat generation, and improving discharge efficiency. As the voltage platform increases, the battery cell needs a smaller capacity if the total energy storage system capacity is to remain unchanged. The energy storage cell of the low-voltage platform is mostly 100Ah, while the high-voltage platform gradually transitions to 50Ah.

The smaller cell capacity means that more cells need to be connected in series, which puts higher requirements on the consistency and stability of battery manufacturers’ cell products.

Large storage cell trend: “big” in its way

At present, a prominent trend of large energy storage cells is to develop in the direction of large capacity. Leading manufacturers, including Ningde Times, Yiwei Lithium Energy, Penghui Energy, Vision Power, Rupu Lanjun, etc., are actively launching large-capacity, long-cycle cells.

With the increasing scale of energy storage power stations, large cells have obvious advantages in the application field of power energy storage: first, large cells are easier to obtain high volume energy density; Secondly, the use of Pack side parts is reduced, which is conducive to reducing costs; The third is to simplify the assembly process in the integrated field.

At present, 280Ah is the mainstream product of large batteries. The model was first introduced by Ningde Times in 2020. Thanks to its leading position in the energy storage market, downstream system integrators have formed 280Ah as the standard design scheme. In order to leverage or expand the market, other factory battery manufacturers have followed 280Ah.

However, in the past two years, major manufacturers have launched higher-capacity products, which have the momentum of catching up with 280Ah. For example, Yiwei Lithium Energy launched 560Ah special battery for energy storage, vision Power launched 305Ah battery, Rupu Lanjun released 320Ah energy storage battery, and Haiji New Energy launched 375Ah battery.

Some insiders pointed out that the introduction of larger capacity cells by manufacturers is an important product competition strategy, just like the photovoltaic size dispute and the trend of large-scale fans.

However, high-capacity cells also face challenges. First of all, the volume and capacity of the battery cell increase, resulting in the deterioration of the heat dissipation performance of the battery cell; Secondly, the production efficiency of large cells is low, which is far less than the production efficiency of 50Ah and 100Ah.